EQUIPMENT

Bridgeport EZ TRAK

milling machine

This machine has a special meaning to me. It belonged to my dad, and when he retired at 87 years old he decided to pass it on to me. I felt very proud that I must have shown him something that made me trustworthy of his pride and joy.

I always remember him saying that one day he would own a Bridgeport mill. The one he ended up with actually turned out to be a very early CNC mill. It is a 2 axis mill, so its capabilities are a bit limited in a world of 3, 4, 5, & even 6 axis machines. But the old dinosaur still holds true tight tolerances and does make some small production runs easier than I straight manual milling machine.

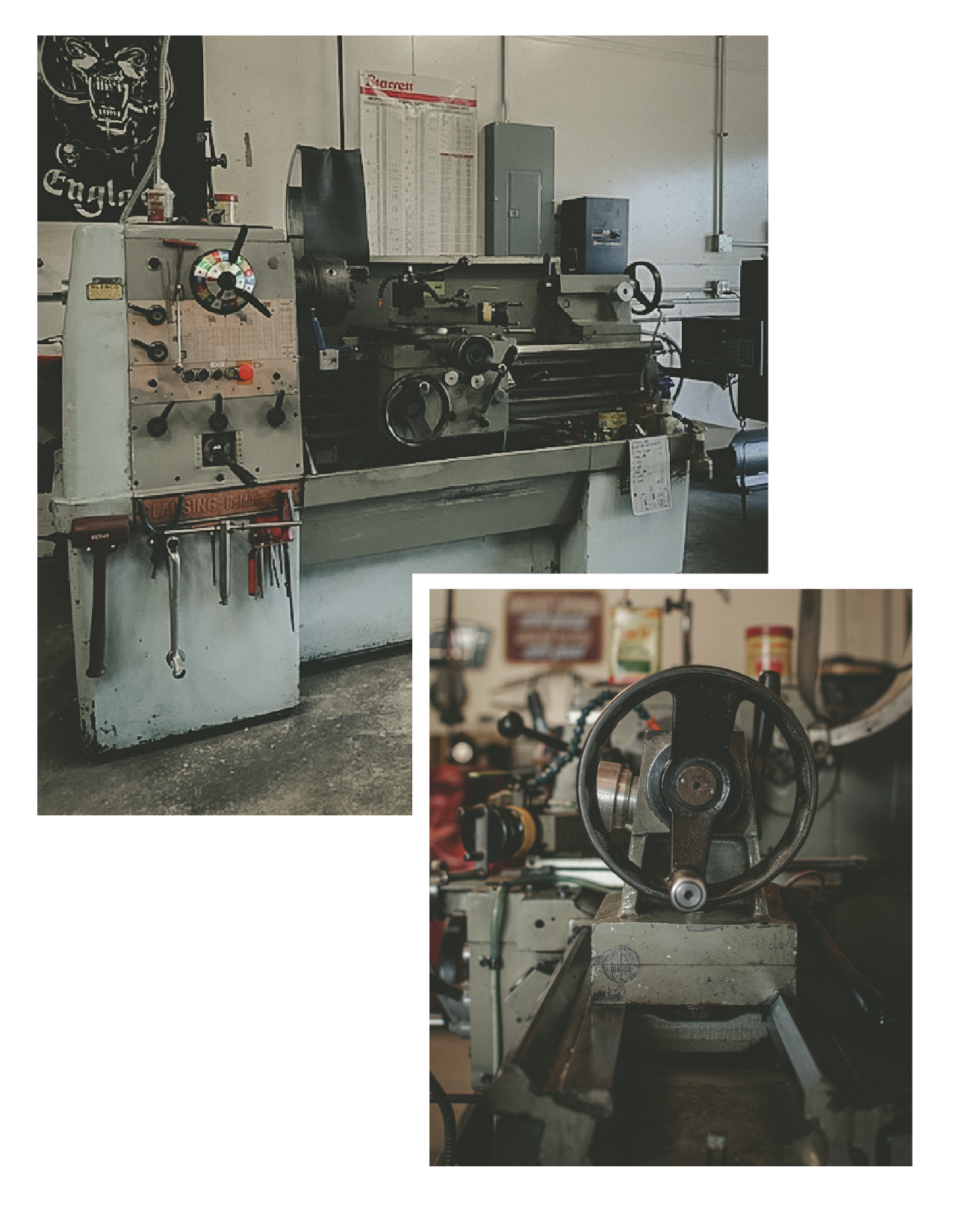

Clausing Colchester

15” metal lathe

When I was 13 my dad put me to work making some simple production parts on a Logan lathe. I am pretty sure this was a violation of some child labor laws but I think since I wasn’t actually getting paid I wasn’t technically “working” in his mind. But I digress.

Needless to say, I got very familiar with turning machines. Everything from simple outside diameter turning to internal boring, threading, and knurling were all skills I learned in that machine shop. Before I started Angry Customs, I was working for a friend who manufactures firearms; I ran a Clausing lathe he had. I hadn’t worked on a lathe for a long time prior to this but it was much like riding a bike, and I picked it back up fairly quickly.

When I moved Angry Customs out of my 400 sq. ft. to its current location, I decided a lathe would be a necessary piece of equipment to own in addition to the Bridgeport mill. I came across this machine on eBay and it has proven to be worth every penny; all 500,000 of em. Love the machine… hate the two-tone paint job somebody thought was a “good idea”.

MILLER DYNASTY

200DX GTAW welder

Last but not least is probably my favorite piece of equipment I own. The very first welder I learned on was a Millermatic 251 GMAW welder, then a Miller Trailblazer gas-powered SMAW machine, then a Miller Synchrowave GTAW machine. Have you noticed a pattern here?

Miller welders are some of the finest around (in my opinion), and they are made in (you guessed it) the USA! So it was an obvious choice when it came time for me to drop the coin on a welding machine. I have welded with a lot of different brands of machines— most are excellent machines and all quite capable of getting the job done, I just prefer to “dance with the one you brought”. I use a Weldcraft water-cooled torch, cooled by a Miller Coolmate 1. The torch is controlled by a Miller fingertip control due to my two dead legs. Getting used to a fingertip control after using a foot pedal for so long still proves to be a challenge many years later. Welding is still my favorite passion, this is why my Dynasty 200dx is my favorite piece of equipment.

OTHER EQUIPMENT INCLUDES:

Tennsmith 24” box pan brake

Di-Acro no. 12 hand shear

Pexto burnishing tool